WAITING six months for your house to be built? Soon, you will "print" a home in less than a day.

Once the domain of tech geeks, 3D printing is now having a serious impact on the wider world.

First it was prototype shapes for designers.

Then it was models and some moulded medical components.

Now, its lego pieces, guns, games and replaceable mechanical parts.

Next, it's your home.

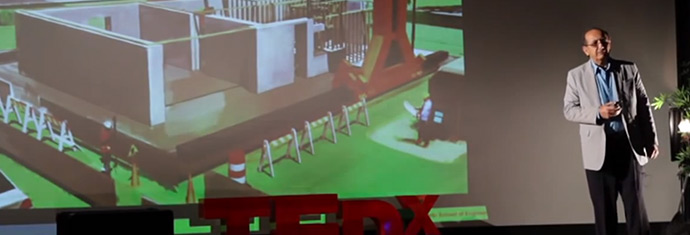

Professor Behrokh Khoshnevis, from the University of Southern California, has explained how a concrete-style material could be used to "print" structures and walls three times stronger than standard concrete in a process he calls Contour Crafting.

Square walls and windows could quickly become a thing of the past: there is no need for convenient mass-produced flat-pack materials here.

Exotic housing designs will be limited only by the imagination - and gravity, Professor Khoshnevis said.

And he says costly, slow and labour intensive construction processes will become a thing of the past.

"Printing" concrete works in much the same way as household 3D printers print shapes out of plastic: a pool of raw material is layered into shapes by a "print head", allowed to set quickly, then another layer applied.

When building a house, the scale is much larger but the concept much the same.

A huge gantry would be positioned on rails on the construction site, and multiple large "print heads" would build the house from the ground up - one layer at a time.

Even plumbing and electrics can be inserted by the system.

Where to next?

Professor Khoshnevis believes this construction technique can be applied in space - building bases on the moon, Mars and beyond.

News Limited Network

- August 14, 201212:38PM

Why people still use to read news papers when in this technological world all is presented on web?

Visit my site at karnisze 2 5m